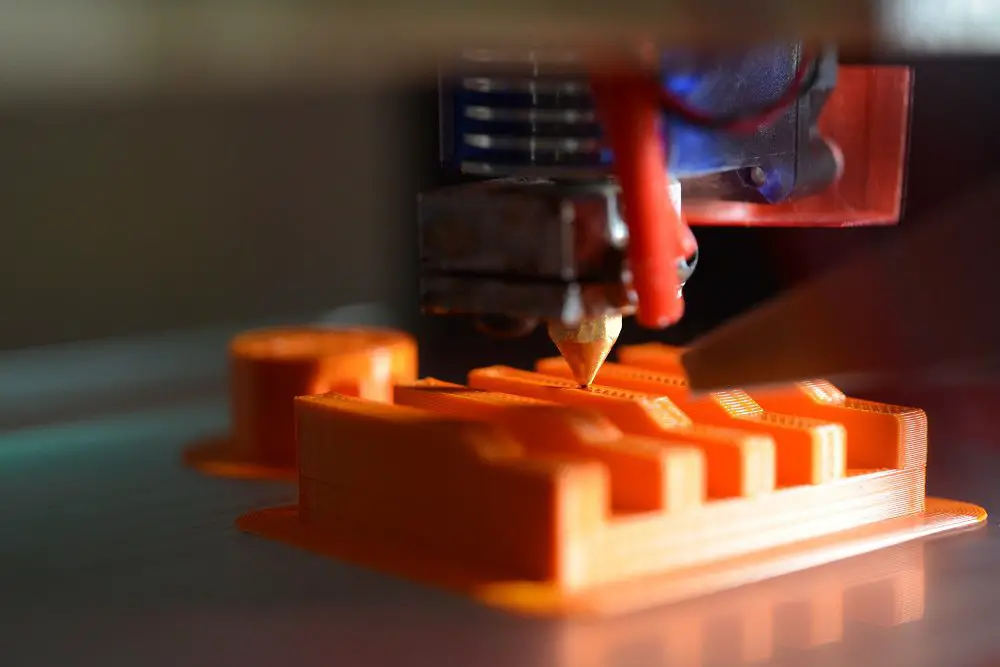

3D printing technology has grown exponentially in popularity in recent years and is revolutionizing the way products are created. The thriving 3D printing industry, also known as additive manufacturing, is an innovative form of printing that allows users to easily and quickly create three-dimensional objects from a digital file. Can you imagine how much time, money, and materials you could save in the manufacturing process? It’s no surprise, then, that it’s gaining traction in a variety of industries, including manufacturing, automotive, aerospace, and medicine.

From the boardroom to the factory floor, 3D printing is exploding in popularity – and for good reason! With its seemingly limitless advantages and potential for future growth, let’s dive into the fascinating world of 3D printing.

In this blog post, we’ll explore the wide array of materials available, as well as how it is revolutionizing industries everywhere. So join us as we explore this exciting technology!

Contents

- 0.1 1. Benefits of 3D Printing

- 0.2 2. Recent Developments in 3D Printing

- 0.3 3. Common Materials Used in 3D Printing

- 0.4 4. Common Applications of 3D Printing

- 0.5 5. Cost of 3D Printing Compared to Traditional Manufacturing

- 0.6 6. 3D Printing Safety and Environmental Impacts

- 0.7 7. Promising Future of 3D Printing

- 1 The Wrap Up

1. Benefits of 3D Printing

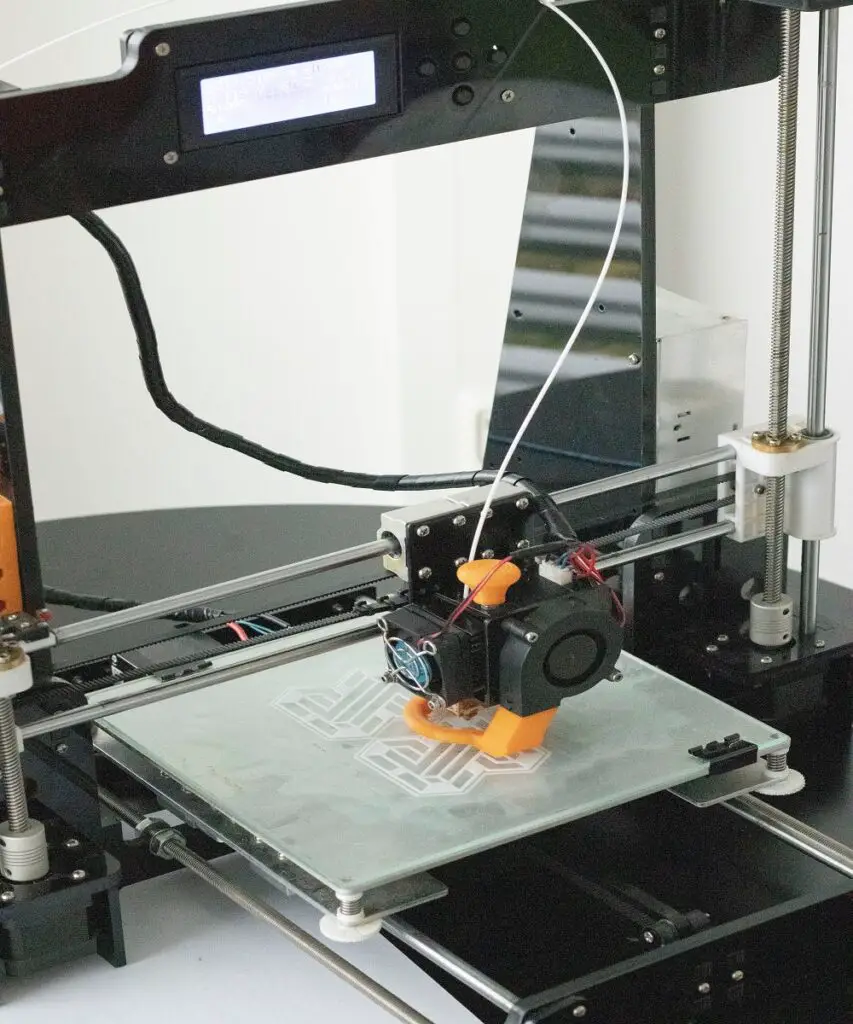

3D printing is a game-changing technology that has gained popularity in recent years. Its numerous advantages have made it a popular choice for both businesses and individuals. One such advantage is the ability to produce complex designs quickly and easily that would otherwise be time-consuming and difficult to manufacture. It also enables greater customization and personalization, allowing users to create items that would be impossible to produce using traditional manufacturing methods.

You wouldn’t want to miss out on it because 3D printing is faster and less expensive than traditional manufacturing processes, saving businesses time and money in the long run.

2. Recent Developments in 3D Printing

Material advancements are one of the most exciting recent developments in 3D printing technology. Previously, materials were limited to plastic, but 3D printers can now produce objects made of metal, ceramic, and even human tissue. The variety of materials is also expanding, with new polymers and composites being developed on a daily basis. What’s more, new software that makes it easier to customize the design of objects is becoming available. These advancements have increased its popularity by making it more accessible and cost-effective.

The Price and Availability of 3D Printers

Another factor driving the trend is the low cost and widespread availability of 3D printers. Previously, 3D printers were prohibitively expensive for most people, with prices ranging from thousands to tens of thousands of dollars. However, 3D printers can now be purchased for as little as a few hundred dollars, making them much more accessible and affordable to the average consumer.

The dawn of the 21st century has brought forth an explosion of new technologies that have made life easier and more enjoyable. One of the most exciting of these is 3D printing. It has become increasingly popular in recent years, and now it’s easier than ever to find and purchase a 3D printer. There are now a variety of stores that sell 3D printers. From electronics stores to online retailers, there are plenty of options for those looking to buy a 3D printer. Now, it’s a breeze to find the perfect 3D printer to suit your every need. Get ready to unleash your creativity and enter a world of endless possibilities.

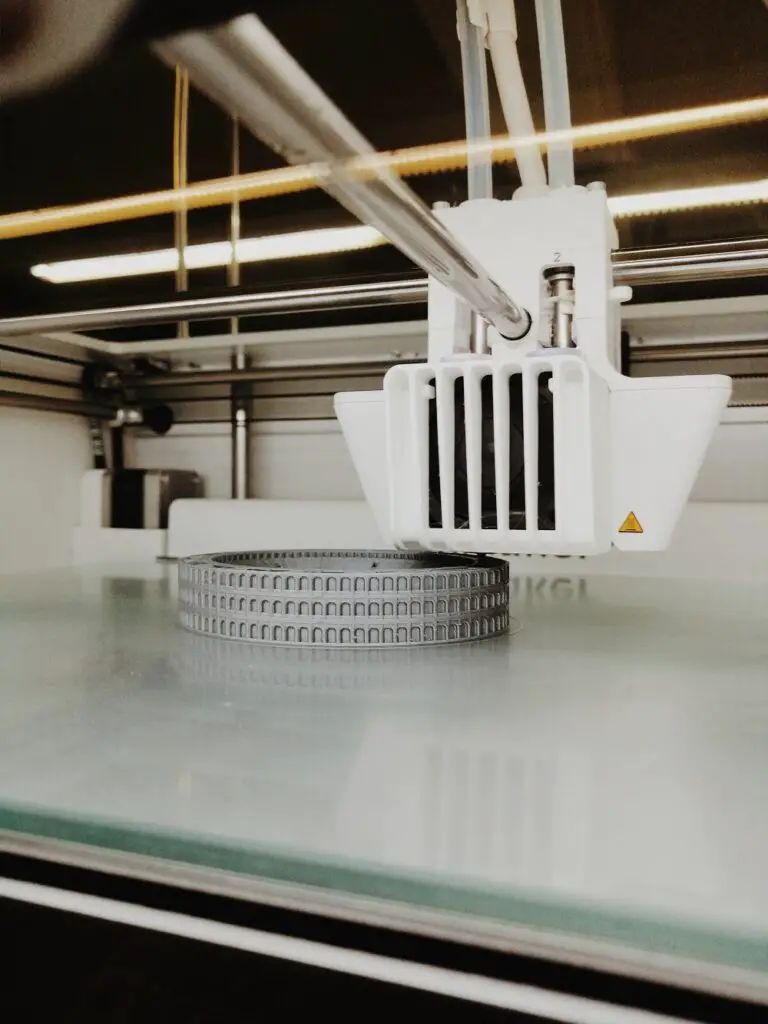

3D printing has revolutionized what’s possible, and we can hardly wait to witness the amazing advancements that the future will bring! For years, the idea of creating physical objects directly from digital designs seemed like something out of a sci-fi movie. But, with advancements in 3D printing technology, it has become a reality.

3. Common Materials Used in 3D Printing

There are numerous materials that can be used in 3D printing. PLA, ABS, nylon, and polyester are some of the most commonly used materials. PLA, or polylactic acid, is a biodegradable thermoplastic derived from renewable resources such as corn starch or sugar cane. ABS, or acrylonitrile butadiene styrene, is a petroleum-based thermoplastic that is commonly used in everyday plastic objects.

Nylon, on the other hand, is a strong, lightweight plastic that is well-known for its strength and durability. Polyester, also known as polyethylene terephthalate, is a strong and lightweight plastic with excellent flexibility and heat resistance. These are just a few of the materials that are commonly used, and as technology advances, so do the materials. (We’ll keep you posted as soon as we have new information!)

4. Common Applications of 3D Printing

Custom part manufacturing is one of the most common applications of 3D printing. Instead of relying on mass-produced components, many businesses can now customize parts to meet their exact specifications. 3D printing also lowers the cost of prototyping and aids in the development of high-precision components.

Another widely used application is the manufacture of medical implants and prostheses. Technology has enabled the development of implants that are custom-made to fit a patient’s body and perform better than traditional implants.

Third, it can be used in the manufacturing of tools. It enables the creation of highly precise and lightweight equipment. Everything from wrenches to medical instruments is included.

Lastly, it’s used in the production of consumer goods like home decor, toys, jewelry, and clothing. Custom items that are both fashionable and affordable are now possible thanks to advances in technology. This has increased consumer appeal.

5. Cost of 3D Printing Compared to Traditional Manufacturing

One of the primary benefits of 3D printing over traditional manufacturing is its low cost. Unlike traditional manufacturing, which requires multiple machines, production lines, and a significant amount of labor, 3D printing only requires one machine and one operator.

Besides this, it saves time and money by removing the need for expensive tooling and prototyping, as well as the waste associated with traditional manufacturing. So it is significantly less expensive than traditional manufacturing, making it an ideal option for small businesses and startups.

While the cost of 3D printing varies depending on the material used, the complexity of the 3D printed part, and the service provider, the general consensus is that it has the potential to lower manufacturing costs.

Overall, this technology requires fewer steps and less material than traditional manufacturing, resulting in cost savings. 3D printing, for example, can eliminate the need for machining, welding, assembly, and finishing operations. It also reduces material waste because it produces only the parts required for a specific application.

6. 3D Printing Safety and Environmental Impacts

The safety and environmental impact of 3D printing are factors that contribute to its popularity. 3D printers create objects out of non-toxic, biodegradable, and recyclable materials like plastic, metal, and ceramics. As an outcome, any waste generated is much easier to safely dispose of, reducing the need for hazardous chemical waste disposal. And 3D-printed objects use less energy and have a lower carbon footprint than traditional manufacturing methods. They are a viable and environmentally friendly business option.

Traditional manufacturing methods had been the primary method of creating products for many years, but with the rise of 3D printing, things are beginning to change. A small business can invest in 3D printing technology. They can seize the opportunity to create products with a significantly lower carbon footprint and energy consumption. Their products can quickly gain attention, and soon they expand their reach.

7. Promising Future of 3D Printing

3D printing has already had a significant impact on the world, and its potential for the future is only growing. It is transforming the way we design, create, and manufacture products, and it has the potential to completely transform traditional manufacturing processes. It has enabled us to produce complex, customized, and functional parts at a fraction of the cost and time that traditional manufacturing methods require.

The future is looking brighter with the advancements in 3D printing. It has opened up a world of possibilities, allowing us to print items that have previously been unimaginable.

Custom medical implants are now a reality, allowing us to create the exact shape and size that a patient needs, with the materials and designs that best suit their individual needs. The same technology is being used to create food, from cakes to hamburgers, providing an efficient and cost-effective solution for restaurants and other food establishments. Even entire homes are now being printed, with companies and individuals using 3D printing technology to create their own custom homes, with walls and other structural elements printed right on-site.

The Wrap Up

So you are probably planning to make the most of 3D printing this year. Its applications appear to be limitless, and its potential to revolutionize business is enormous! It has the power to create a world of possibilities, from medical marvels to manufacturing miracles — all that is needed are the right materials and tools. And with tech advancing every day, who knows what incredible creations we can see in the future! Are you prepared for them?