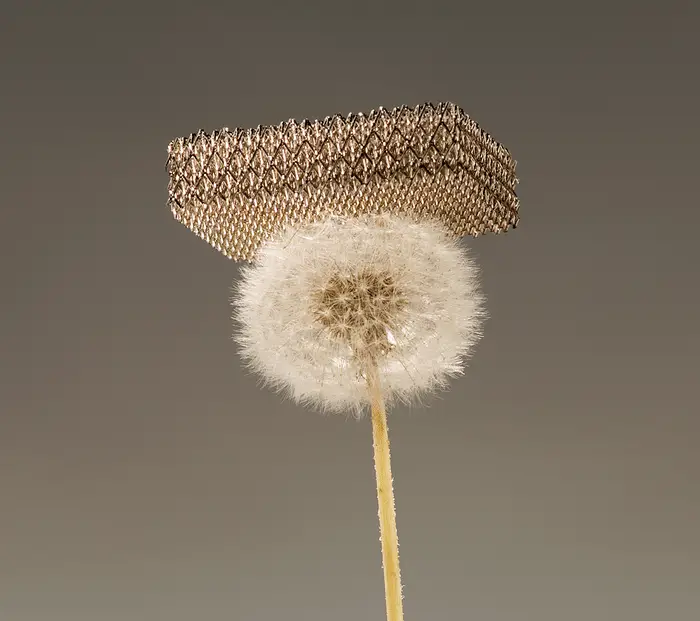

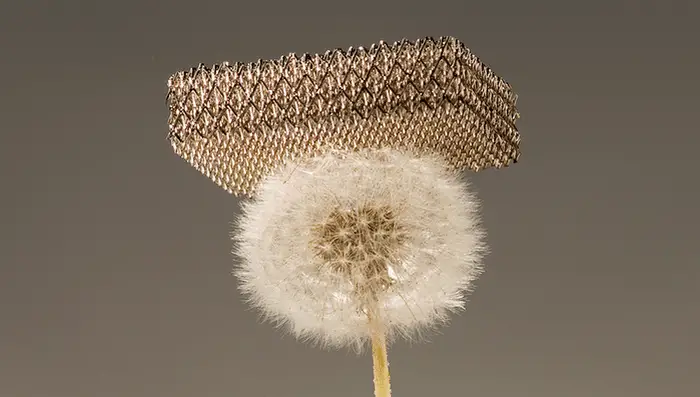

Imagine a metal structure 100 time lighter than Styrofoam yet retaining immense, inherent strength. It’s real and it was developed by researchers at HRL Laboratories, a joint venture between Boeing and GM, back in 2011. Boeing has now released a promotional video showing the incredible versatility of the product that they have named Microlattice so we assume it is close to a commercial reality as well.

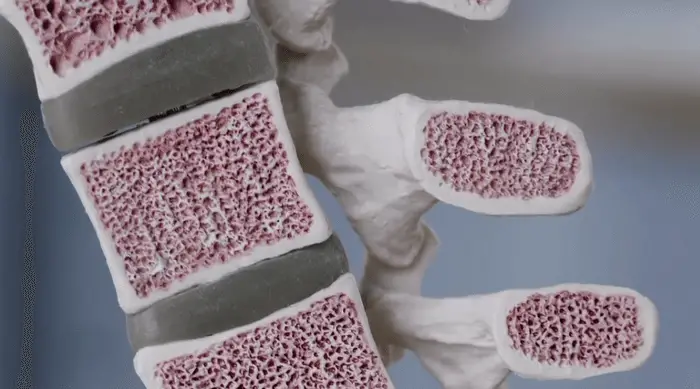

As is so often the case, the innovation was based on nature… the structure of bones. Bones have a dense, strong exterior but are mostly air cavities internally. If our bones were solid, we’d be much heavier and would require a significantly larger musculature to carry ourselves around. Birds have an even lighter bone density than other animals yet those bones are strong enough to handle wind buffeting and ‘crash landings’. Microlattice mimics nature by having a rigid metal exterior while being 99.9% air by volume.

The microlattice is built up of masses of interconnected nickel tubes with a wall thickness of just 100 nanometres. That’s about 1,000th the thickness of a human hair! These open cells allow the structure to have a massive compression potential meaning that it can absorb significant force without breaking.

It’s obvious to see how microlattice could be used in future air and spacecraft to make them lighter, stronger and more fuel efficient but the same technology will offer the same benefits to the automotive industry.

The following video gives more detail.

You can read the original press release here…

As always, we live in interesting times! What’s your take? Where can you see microlattice being used? Share your thoughts via the comments box below!