If you live in rural Australia, you know all about mud-dauber wasps. Incredibly industrious, they spend the summer months finding wet soil, clay or mud and then using it to make their egg sacs… all over your walls! The sacs are tough and protect the eggs from predators until they hatch.

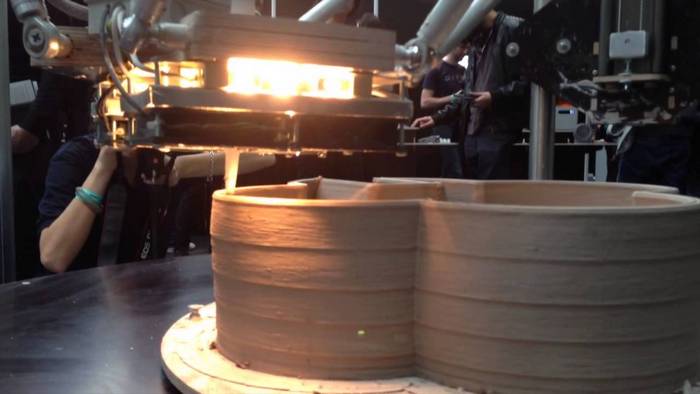

The WASP in this article is a six metre (20 ft) high, 3D printer that uses mud to build strong houses for people! Designed and manufactured in Italy by WASP (World’s Advanced Saving Project), the printer exudes a mix of mud and fibre to create what appears to be similar to fibrous plaster. To date, the fibre used is wool but I can see coconut fibre being a very viable and inexpensive alternative!

WASP already has a commercial line of innovative 3D printers including a swappable clay extruder for those wanting to work with ceramics. This concept has been put on steroids to create the home building model dubbed Big Delta!

Click on any image to start lightbox display. Use your Esc key to close the lightbox. You can also view the images as a slideshow if you prefer.

The printer can be disassembled, relocated and then reassembled in four hours (plus travel time) making this ideal for remote housing projects.

3D printed houses are a commercial reality today. Get used to the idea because the technology is evolving rapidly. Here’s a 3D printed apartment block…

Are you ready?